Menu

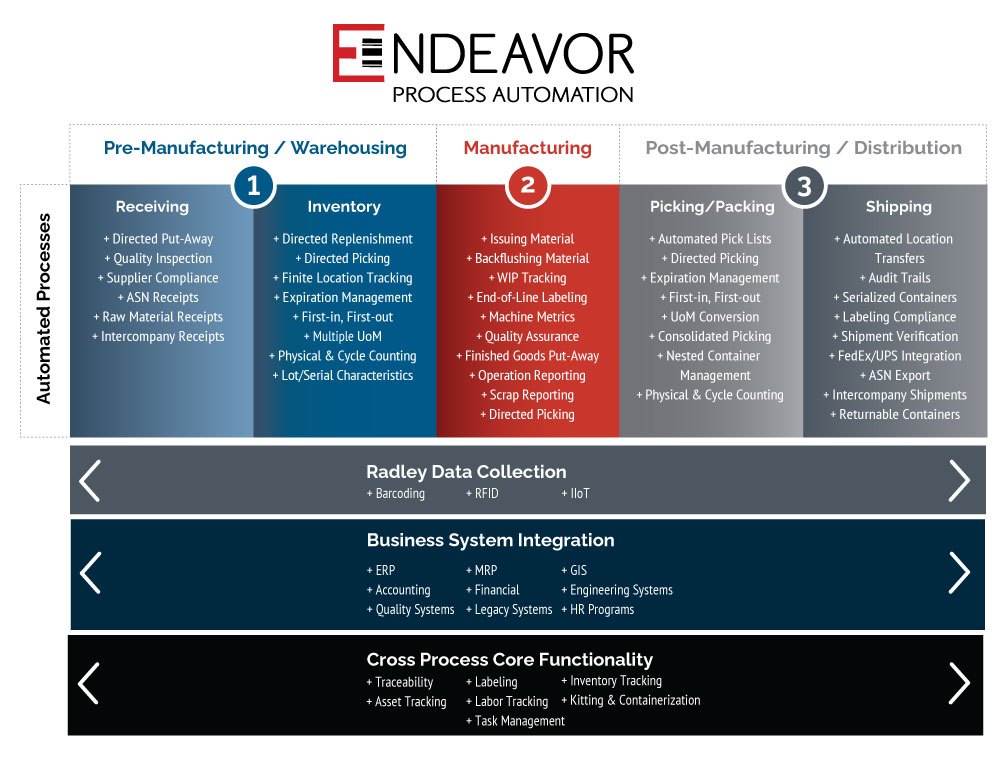

Production-Oriented Solutions for Manufacturers and Distributors.

Radley develops and implements Manufacturing, Warehouse and EDI software solutions aimed at improving efficiency and productivity for your business.

EDI Solutions

Explore

Process Automation

Knowledge Center