When it comes to the manufacturing industry, “efficiency” is the magic word. In the pursuit of lean manufacturing standards, efficient inventory management reduces costs and eliminates waste.

That’s why strategies like just-in time inventory (JIT) are so widely used today. JIT allows the receiving of goods only as needed in the production process, eliminating the need for excess inventory.

Thus, it increases efficiency by decreasing waste and reducing inventory costs. Manufacturers can see many benefits from just in time inventory management systems:

Improved cash flow.

With JIT inventory ordered and received as needed, there is no for safety stock. As a result, companies can see lower carrying costs from reduced inventory levels on hand.

Reduced lead times.

When a product experiences high customer demand, the assembly line can respond without delay. At the same time reducing production runs on items with decreased demand.

Better supplier relationships.

The need for quality raw materials, delivered on-time ensures a company only works with reliable suppliers. This can also cut under-performing vendors, reducing the time spent on vendor relations.

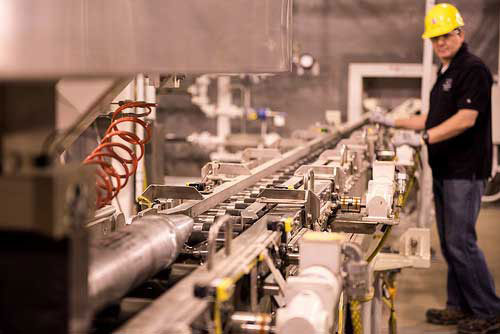

Within JIT inventory management itself, opportunities exist to increase manufacturing efficiency even more. For instance, kitting is a common method used to simplify the material handling.

The kitting process involves grouping the parts needed during the manufacturing process. Then, issuing the resulting “kit” as a single package. Using parts within a kit at, or around the same time, is more efficient than supplying them individually.

When using JIT and kitting together, efficiency improves. It minimizes delays in the manufacturing process and reduces material handling assembly time.

JIT kitting improves quality by ensuring that the right parts are always available. Also, it limits the options of parts to the operator.

In short, kitting can help reduce the need for assemblers to search for inventory and pull parts. Plus, kitting reduces machine downtime due to parts availability.

Don’t Go it Alone.

As with any manufacturing process, problems can arise if kitting isn’t well managed. For example, if operators remove parts from complete kits, the result is a ripple effect. This can cause delivery delays, production slowdown, warehouse inefficiency and more.

With the right software and consulting, you too can access the benefits of JIT manufacturing, while avoiding the pitfalls. Is your company implementing a lean management strategy? If so, a just in time (JIT) inventory system with kitting functionality may help boost efficiency while lowering costs.

Radley provides software solutions to promote effective supply chain management. Our team of in-house experts provide consulting, software, hardware, training and support. Contact us today and re-Engineer your business process for greatest efficiency!