In a post-pandemic world, is smart manufacturing the future? Let’s first define, “What is smart manufacturing?”

Smart manufacturing uses digital technology to predict, coordinate, and execute manufacturing tasks. Solutions like connected sensors, AI and automation bring accuracy, efficiency and transparency to manufacturing.

Industry 4.0 and the “Smart” Revolution

From steel mills to silicon factories, technology has always played a crucial role in manufacturing. But until the last few decades, it still relied on user input to log and distribute information. Even when accompanied by manufacturing software and robotic devices, executing processes and tracking data still required eyes on the ground. This left room for error and a greater need for human personnel to carry out common tasks.

The “smart” revolution ushered in by smartphones changed this equation. Devices with internet connections made it possible to share information anytime, anywhere. Rather than relying on manual input, smart devices could observe and report, replacing human interaction.

The Rise of the IoT

With the Industrial Internet-of-Things (IIoT), this concept expanded. Now, IoT devices can keep tabs on an endless number of items and their characteristics. For instance, intelligent sensors gather and share data like location, weight, or other data points.

These technologies provide a vast amount of data, which lies at the heart of smart manufacturing operations. Armed with data for demand and resource planning, manufacturers can now enjoy a holistic view of their entire operation. For example, they can track raw materials and goods through the supply chain with pinpoint accuracy thanks to IoT sensors. On the shop floor, sensors combined with automated machines can perform tasks like sorting and packaging.

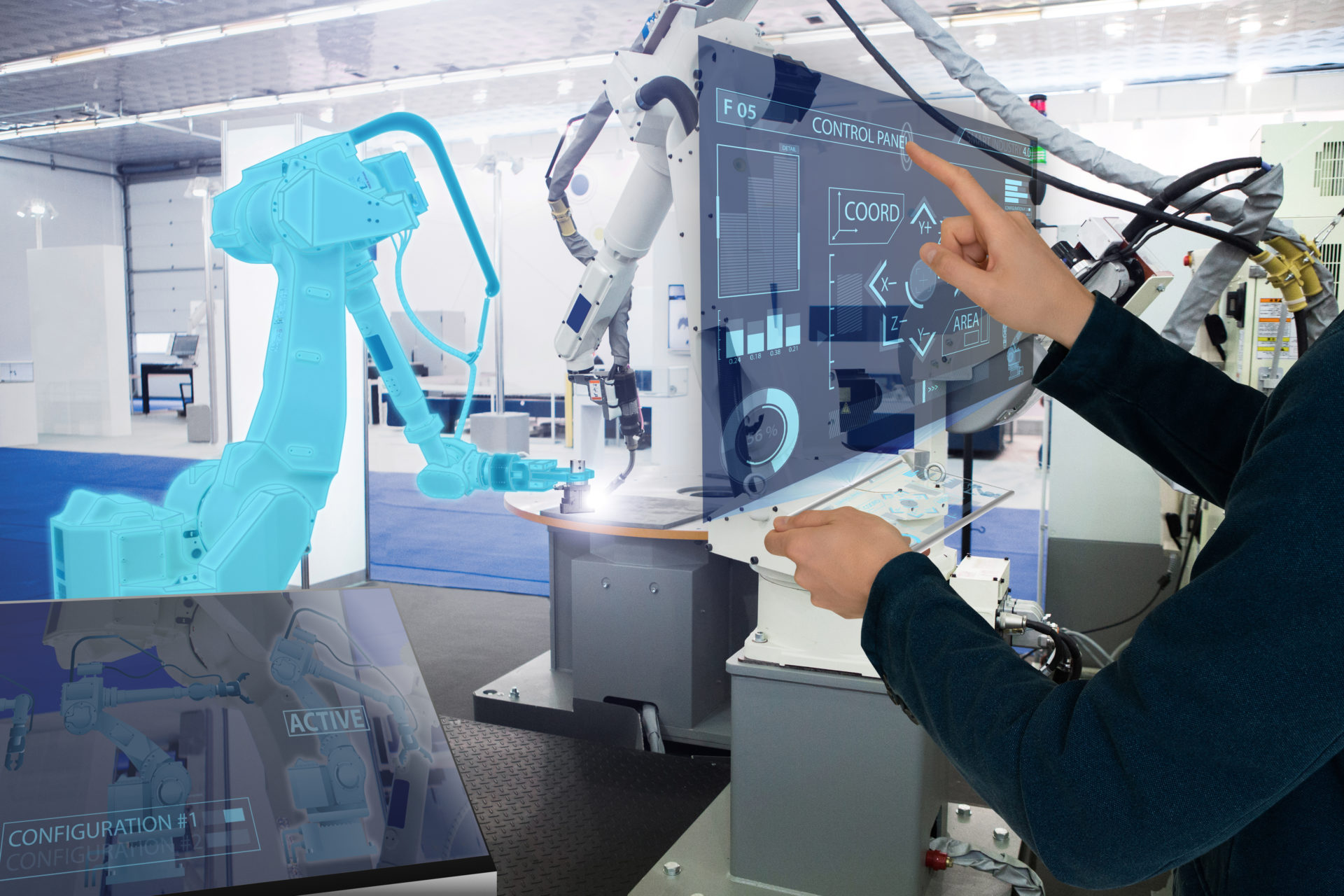

Robots to the Rescue?

Robotics and 3D printing capabilities also play a role in smart production processes. Along with human workers, AI-enabled robots can assemble items with speed and agility. Likewise, 3D printing enables rapid prototyping and development. In turn, this cuts down on waste and allows for quick creation of products, parts, and accessories.

Looking to the Future of Manufacturing

Smart manufacturing allows manufacturers to source, build, and distribute products with efficiency. As the manufacturing sector recovers, the need for efficient and agile processes will only increase. With greater insights, accuracy, and automated workflows, smart factories are the future.